Zinc electroplating is a popular technique used to coat metals with a thin layer of zinc. This process offers protection against corrosion and enhances the appearance of metal surfaces. But when people ask, “What color is zinc electroplating?”, the answer isn’t as simple as a single shade. The color of zinc electroplating can vary greatly depending on several factors such as the method of plating, the chemicals used in the bath, and even the thickness of the zinc coating.

What Color Is Zinc Electroplating?

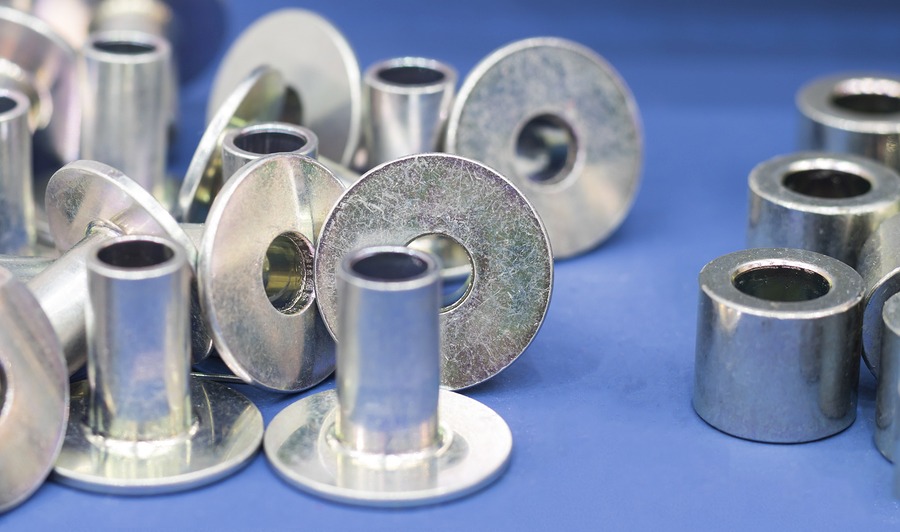

Zinc electroplating, in its purest form, is typically a silvery-grey color. This is the standard appearance for most zinc-coated materials and is largely due to the way zinc atoms are deposited onto a metal surface during the electroplating process. The shiny, silvery finish is clean, durable, and widely used across various industries.

But here’s the twist: while silvery-grey is the most common color, zinc electroplating can take on different hues depending on the factors involved in the process. That’s right—zinc electroplating can look like anything from a golden hue to a dark, almost black finish. So, let’s take a closer look at these various colors and understand why they happen.

Common Colors of Zinc Electroplating

The Default Color: Silvery-Grey

When most people think about zinc electroplating, they picture that shiny, almost metallic silvery-grey finish. This is the natural result of the plating process, where zinc is electrochemically deposited onto a metal surface. The final look is smooth and shiny, providing not only aesthetic appeal but also an effective corrosion-resistant coating.

The silvery-grey color happens because of the intrinsic properties of zinc. It forms a layer that reflects light in a way that gives it this metallic appearance. This is by far the most common finish and is typically used in industries where both protection and a neutral color are desired.

Yellow Zinc Plating (Golden Finish)

Now, this is where things get interesting! Zinc electroplating can sometimes have a yellow or golden tint, which is a result of chromate conversion coatings applied after the plating process. This yellowish color doesn’t happen by accident—it’s a controlled process designed to enhance the corrosion resistance of the zinc plating.

Yellow zinc plating is often used when the goal is to create a more visually appealing finish without sacrificing durability. You’ll commonly find this in the automotive industry, on bolts, screws, and other fasteners. The reason for the yellow color is the addition of chemicals that react with the zinc layer, forming a thin but tough protective film.

In addition to offering superior protection, the golden finish provides a distinct look that stands out in many industrial applications.

Black Zinc Plating

For a more dramatic and sleek appearance, black zinc plating is another common choice. This finish is achieved by adding special chemicals to the electroplating bath that turn the zinc layer dark. The black finish isn’t just for looks; it provides enhanced corrosion resistance, making it an ideal option for parts that will be exposed to harsh environments.

Black zinc electroplating is frequently used for items like electronic components, machinery, and automotive parts, where both protection and a professional appearance are essential.

Clear/Transparent Coatings

Lastly, we have the clear or transparent coating. Although this might sound like a contradiction (after all, who wants a “colorless” finish?), it’s actually one of the most functional color options. After the zinc plating is done, a clear chromate conversion coating is applied. This transparent layer enhances the plating’s resistance to corrosion while maintaining the original look of the zinc coating.

The benefit here is that the coating doesn’t interfere with the natural shiny grey finish. It’s often used when the goal is to add a protective layer while keeping the look of the raw zinc intact. You’ll see this type of plating on various construction materials, hardware, and even some electrical components.

Factors Influencing the Color of Zinc Electroplating

So, what causes these different colors to appear in the first place? Well, it all boils down to a few key factors that play a crucial role in shaping the final look of the zinc coating. Let’s dive into them:

Thickness of the Zinc Layer

The thickness of the zinc coating is directly linked to the appearance of the final product. Thicker layers of zinc generally result in a darker or more saturated finish. In contrast, thinner coatings tend to have a lighter, silvery finish. The amount of zinc deposited can be controlled in the electroplating process, which is why manufacturers have the flexibility to choose the exact finish they want.

Type of Electroplating Process Used

Not all electroplating processes are created equal. For example, barrel plating (which is often used for smaller parts) can lead to a slightly different finish than rack plating (used for larger items). The method used affects the evenness of the coating and, in some cases, the color. This is especially important for manufacturers who are aiming for uniformity in appearance.

Temperature and pH of the Electroplating Bath

The composition of the electroplating bath—including the temperature and pH—can significantly impact the final color of the zinc coating. Higher temperatures can make the coating thicker, which might result in a different shade or hue. Additionally, the acidity or alkalinity of the bath can change the way the zinc interacts with the metal substrate, influencing the final finish.

Use of Additives in Electroplating

Certain chemical additives can be introduced to the plating bath to change the appearance and improve the functionality of the zinc coating. These can include brighteners that help achieve a shinier finish or other compounds that influence corrosion resistance and color. These additives are carefully chosen based on the desired result.

Is Zinc Electroplating Color Important?

You might be wondering: does the color of zinc electroplating really matter that much? Well, the answer is yes—color can be very important, both for practical reasons and for aesthetic appeal. Let’s break it down:

Visual Appeal and Identification

The color of the zinc electroplating can serve as an important visual identifier. For instance, industries often use color-coded zinc finishes to differentiate parts based on their function or application. In the automotive industry, for example, a yellow zinc coating might indicate a part that’s designed to resist a specific type of corrosion. On the other hand, a black finish might suggest that the part is meant for a high-performance application.

Functional Benefits Beyond Aesthetics

While color does play a role in appearance, it’s the functionality of the zinc plating that truly matters. For example, a yellow zinc finish isn’t just for show; it provides extra corrosion resistance due to the chromate conversion coating. Similarly, black zinc coatings are often used because of their superior protection in high-stress environments.

Color as an Indicator of Plating Quality

Another reason color is important is that it can act as a signal of the plating quality. For example, a consistent and even color can suggest that the electroplating was done correctly. If the color is patchy or uneven, it might indicate that something went wrong in the process, and the coating could be compromised.

As you can see, zinc electroplating isn’t just about getting a shiny finish. The process can result in a variety of colors, each serving different purposes. Whether it’s the traditional silvery-grey, the golden hue of yellow zinc, or the dramatic black finish, each color has its unique advantages.

Understanding what color is zinc electroplating and why it changes can help industries make informed decisions about which type of plating to use for their specific needs.

Now that we have explored the basic colors and the factors influencing zinc electroplating colors, let’s dive deeper into the significance of these variations in different industries, the benefits they bring, and how they can be maintained. Understanding these aspects can be extremely useful, whether you’re involved in manufacturing, buying zinc-plated products, or just curious about the technicalities behind this process.

Benefits of Zinc Electroplating Colors

Zinc electroplating offers a range of benefits that extend beyond just visual appeal. The color of zinc electroplating is tied directly to corrosion resistance, durability, and protection. So, while the shiny silver finish might look good on a set of bolts, the color can also tell you about the longevity of the product. Let’s break it down.

Durability and Corrosion Resistance

One of the primary reasons for choosing zinc electroplating, regardless of color, is protection against corrosion. Zinc naturally forms a protective oxide layer when exposed to air, and this helps prevent the underlying metal from rusting. However, when you apply a zinc electroplated finish, this protection is much more robust. Some specific colors offer enhanced corrosion resistance, depending on the additives or coatings used.

- Yellow Zinc: The yellow finish, achieved through chromate conversion, is particularly effective in preventing corrosion. This finish not only boosts the visual appeal but also adds an additional layer of protection that is more resistant to environmental wear, making it ideal for parts exposed to moisture or chemicals.

- Black Zinc: Similarly, the black finish is often applied to high-performance parts that require even better corrosion resistance. The dark coating not only looks sleek but also serves as a tough shield against environmental factors.

- Clear Zinc: Clear coatings provide the classic shiny look of zinc while still offering protection, though they are usually not as resistant as the yellow or black variations.

Cost-Effective Protective Coatings

Zinc electroplating is also cost-effective compared to other coating methods like nickel or chrome plating. It provides an excellent balance between protection and affordability. The color of the plating can also influence how well the coating performs over time, which ultimately impacts long-term costs.

For example, yellow and black zinc coatings are often chosen for their enhanced durability, even though they might cost slightly more upfront than a simple silver finish. However, these colors tend to offer better performance in harsher conditions, saving money in the long run by reducing the need for replacements or repairs.

Environmental and Sustainability Considerations

While zinc electroplating is already considered an environmentally friendly option, some plating methods incorporate eco-friendly additives that help reduce environmental impact. Zinc itself is a relatively sustainable material, and many industries are increasingly choosing plating options with lower environmental footprints. The clear coatings, for example, might use fewer chemicals, making them more appealing to manufacturers focused on sustainability.

How to Maintain the Color of Zinc Electroplating

Once you’ve got that perfect color on your zinc-plated item, the next step is to ensure that it lasts. Zinc electroplating is durable, but like all materials, it requires proper care and maintenance. Here are some practical tips on maintaining the appearance and longevity of the coating.

Cleaning Zinc Plated Surfaces

One of the easiest ways to maintain the appearance of zinc electroplating is to regularly clean the surfaces. Proper cleaning prevents the buildup of dirt, oils, or other contaminants that can degrade the finish. The key is to use gentle methods that won’t scratch or damage the zinc surface.

- Use mild soap: Mix soap and water to create a mild cleaning solution.

- Avoid harsh chemicals: Do not use harsh cleaning agents like bleach, as these can affect the finish.

- Soft cloth or sponge: Use a soft cloth or sponge to gently clean the surface, avoiding abrasive materials.

For areas that are particularly dirty or have built-up grime, a non-abrasive cleaner designed for metals can be used. Always rinse thoroughly to remove any residue.

Preventing Color Fading or Damage

While zinc electroplating is naturally resistant to corrosion, it’s important to take steps to prevent color fading or damage, especially if the plating has been done with a specific coating like yellow or black zinc. Here are some tips for preserving the finish:

- Store items in dry conditions: Keep zinc-plated items away from high humidity or direct sunlight when not in use.

- Avoid abrasive surfaces: Never scrub or buff the plated surface too harshly, as this can wear away the protective coating.

- Protect from chemicals: Harsh chemicals or solvents can erode the plating and damage the color. For industrial items, be sure to avoid exposure to such substances when possible.

For items exposed to outdoor elements or harsh conditions, it’s a good idea to apply a clear protective coating after the zinc plating is applied. This can add an extra layer of protection and help maintain the original color and finish for much longer.

How Does Zinc Electroplating Compare to Other Coatings in Terms of Color?

When it comes to plating, zinc isn’t the only option. Chromium, nickel, and even galvanizing are other popular methods, each with its own set of color characteristics and advantages. Let’s compare zinc electroplating to a few of these to help you understand how zinc stands out.

Zinc vs. Chrome Plating

Chrome plating is often used for its high-shine finish and reflective surface. In comparison, zinc electroplating offers a more subtle, silvery-grey look, though it’s not as reflective as chrome. Chrome plating tends to be more durable in terms of scratch resistance, but zinc offers better corrosion protection and is usually more cost-effective.

- Chrome Plating: Typically bright and shiny, chrome offers a sleek, polished look. However, it is more prone to scratches and discoloration over time.

- Zinc Electroplating: While the finish is often matte or slightly reflective, zinc offers superior corrosion resistance and a more affordable solution.

Zinc vs. Nickel Plating

Nickel plating is often chosen for its sleek, silvery appearance. Like zinc electroplating, nickel also provides corrosion protection, but nickel tends to have a more yellowish or slightly gold tint. Zinc, on the other hand, has a more neutral silvery finish, which may appeal to those looking for a less pronounced color.

- Nickel Plating: Tends to offer a more goldish or yellowish hue. It’s also more expensive than zinc plating and may be used for high-end finishes or electrical applications.

- Zinc Electroplating: Zinc is generally a more cost-effective solution for corrosion resistance. It’s often preferred for its neutral appearance and flexibility.

Zinc vs. Galvanizing

Hot-dip galvanizing involves coating a metal with a thick layer of zinc. This results in a much thicker coating than electroplating and is typically used for larger industrial applications. The color of galvanized steel is typically grey or dull, with some variations depending on the zinc content.

While galvanizing provides excellent corrosion resistance, the finish is more utilitarian compared to the cleaner, more polished finish of zinc electroplating.

- Galvanizing: Typically more matte with thicker coatings, ideal for outdoor structures.

- Zinc Electroplating: Provides a more polished and aesthetic finish, often used for smaller components and indoor applications.

Frequently Asked Questions (FAQs)

Can Zinc Electroplating Be Customized in Color?

Yes, it can! While silvery-grey is the default color, manufacturers can customize zinc electroplating finishes by applying chromate conversion coatings in various colors, such as yellow, black, or clear. This process allows for flexibility in both the appearance and the protection provided by the plating.

Does Zinc Electroplating Rust or Change Color Over Time?

Yes, over time zinc electroplating can change color if exposed to harsh environmental factors like moisture, heat, or chemicals. The surface may oxidize, causing it to darken or change hues. However, a clear coating can help prevent such changes and maintain the finish for much longer.

What Are the Best Color Choices for Outdoor Use?

For outdoor use, yellow zinc plating is often the best choice because of its enhanced corrosion resistance. The chromate conversion process used to achieve the yellow finish provides extra protection against environmental elements, ensuring longevity even in tough conditions.

The question of “What color is zinc electroplating?” may seem simple at first, but as we’ve seen, the answer is influenced by a variety of factors—from the thickness of the coating to the specific chemicals used in the electroplating bath. Whether you’re interested in the traditional silvery-grey finish or prefer a more vibrant yellow or sleek black, zinc electroplating offers a wide range of colors with benefits that go beyond aesthetics.

From increased corrosion resistance to enhanced durability, the color of zinc electroplating serves a practical function that can make all the difference in protecting and preserving your metal items. So, the next time you’re considering zinc electroplating for your product, take into account not only the color but also the functional benefits each hue brings!